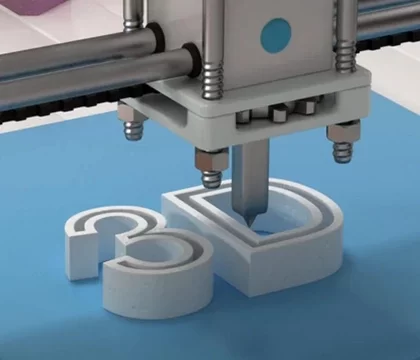

3D printing has revolutionized prototype development, enabling engineers and designers to transform concepts into functional models faster than ever. We can offer 3D printing for rapid prototyping and production in as fast as 1 day to verify compatibility between your PCB design and mechanical parts. Get an instant 3D printing quote with DFAM analysis today.

Functional Prototyping • End-Use Parts • R&D Support

Your Ideal Partner In Industrial 3D Printing

The increasingly developing 3D printing technology is bringing opportunities, flexibility, and efficiency to the manufacturing industry.

Whether used for building functional rapid prototypes, small-to-medium batch production, or large-scale mass production, 3D printing offers significant advantages over traditional manufacturing methods.

For a start, product prototyping and development can be significantly accelerated, product customization and feature integration can be implemented and verified faster, and overall costs can be reduced, especially in the early stages of the product lifecycle.

High Performance Materials: PEEK/ CF-PEEK, PEKK/ CF-PEKK, ULTEM™/ CF-ULTEM, PPSU

Advanced Engineering Materials: PC/ CF-PC/ ESD-PC/ CF-PA

Prototyping Materials: ABS/ CF-ABS, ASA/Nylon/Resin/Metal

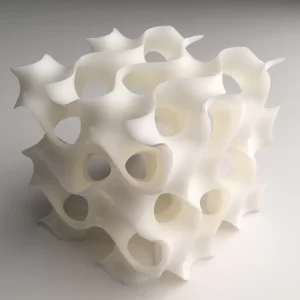

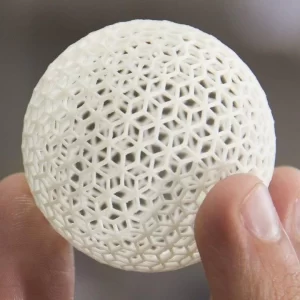

Prior to directly launching mass production, engineering and designers benefit from 3D printing functional prototypes that can help verify fit, functionality and optimum integration with other components or group parts, accelerating the iterative development cycle and time to market.

In many cases, the mechanical properties and surface characteristics of 3D printed parts has perfectly met and exceeded customer expectations, allowing them to be used in actual products.

Low volume production

Additive manufacturing is frequently more cost-effective than other traditional manufacturing methods, allowing the rapid production of end-use parts at scale, reducing tooling and inventory costs and accelerating the time to market.

Jason was extremely helpful in advising materials, the parts were delivered on time and packaged very well.

Engineer

Just to let you know I have received my items and I’m more than happy with the outcome! Thank you for all your help!

Architect

Excellent service friendly staff and a very fast turn around Thank you Guys

Developer

We received the part. The part is well done. I would like to thank you for your attention and fast reply to the emails. I hope in the future will be more occasion to work with you.

University Research

Our technicians provide personalized advice on the use of 3D printing technology based on specific customer requirements:

Post processing is the final stage in the 3D printing process that is used to achieve the desired visual, tactile, and surface requirements for each component.

3DGence America offers to following post processing services:

201, Block S, Hengyu, Science&Technology Park, No.1 Ruiji Rd, Nanlian Community, Longgang District, Shenzhen, China.

+86 755 8487 1176

At RockPCB, LLC. we strive to be your premier partner in technological design engineering, offering comprehensive solutions from circuit board design and layout to software and firmware development. Our mission is to provide applicable, intelligent solutions that propel our clients’ technologies forward.