Electronics Manufacturing Services

As an experienced Electronics Manufacturing Services (EMS) provider in Shenzhen, China, RockPCB excels in PCB layout, PCB fabrication, PCB manufacturing, PCB design, and comprehensive testing of electronic components and printed circuit board assemblies for OEMs.

Electronics Manufacturing Services

Functional Prototyping • End-Use Parts • R&D Support

Your Partner In Electronics Manufacturing Services

+86 755 8487 1176

Comprehensive Electronics Design and Manufacturing Services.

Our in-house experienced electronics engineers and our partners’ state-of-the-art manufacturing facilities will streamline your production processes, enhance product quality, and deliver your electronics quickly and dependably while offering unique social marketing benefits for a competitive edge.

Your Trusted EMS Partner

Access our full suite of end-to-end electronics manufacturing services (EMS), including design engineering support, manufacturing, supply chain management, fulfillment, and end-of-life support. At RockPCB, we’ll make your product prototypes to the most exacting specifications and modify the design for ease of testing and manufacturing, saving you both time and money.

When your product is ready, our supply chain, logistics, and fulfillment infrastructure will ensure your products make it to your customers on time, every time, and built to the highest quality standards.

End-to-End Electronics Manufacturing Services

Our expertise extends well beyond our manufacturing facilities. Access our sophisticated tracking technology to follow your products to and beyond the point of sale, allowing you to gather valuable user data. And once your product has reached the end of its life, we can assist with recycling or refurbishment, making it easy for you to meet your sustainability commitments.From prototype development to volume production to delivery and beyond, RockPCB makes it easy for you to manage the complete life cycle of your product.

Flexible, Customizable, Scalable

Our facilities are designed to execute changes quickly and efficiently, so you can modify your designs without costly production lags. Our substantial electronics manufacturing capacity and our expertise in inventory management allow us to pivot quickly to meet product demand changes, saving you excess inventory expenses or lost sales. Our ISO quality management system ensures the highest level of quality.

Electronics Manufacturing Services Features and Elements

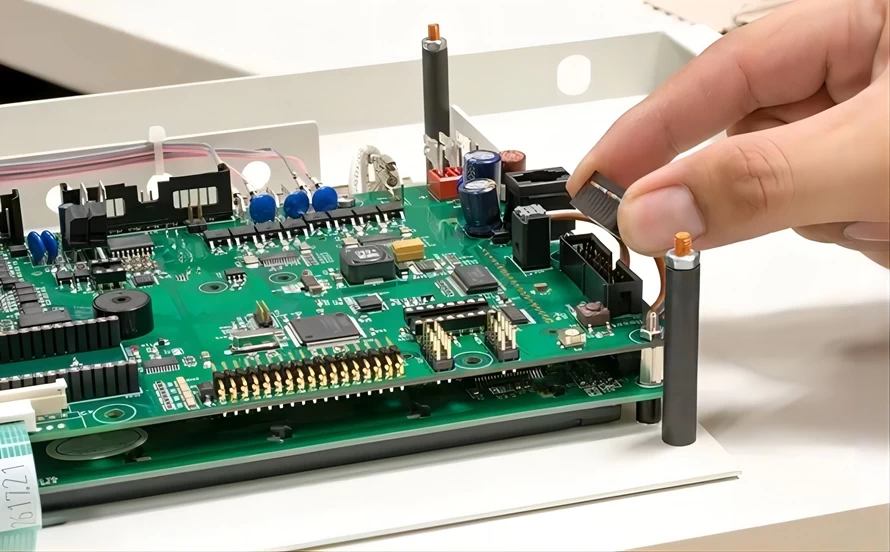

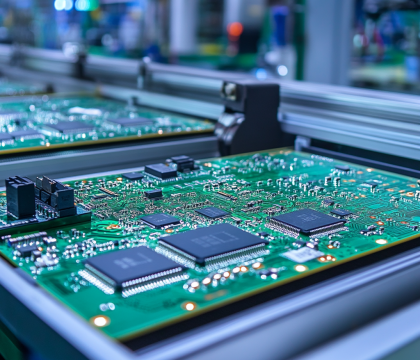

State-of-the-art PCBA Manufacturing

We can offer circuit board assembly services that are quickest than anyone else, so you will get on-time delivery. We use the standard technologies like Thru-Hole (PTH), surface mount (SMT) and mix technologies to provide the best printed circuit board assembly services in China.

Materials Management

Services include procurement and materials management, vendor management, forecasting, and flexible demand and capacity planning.

Product Lifecycle Management

We design our manufacturing solutions around the entire life of the product so your goods will be less expensive to produce and easier to recycle.

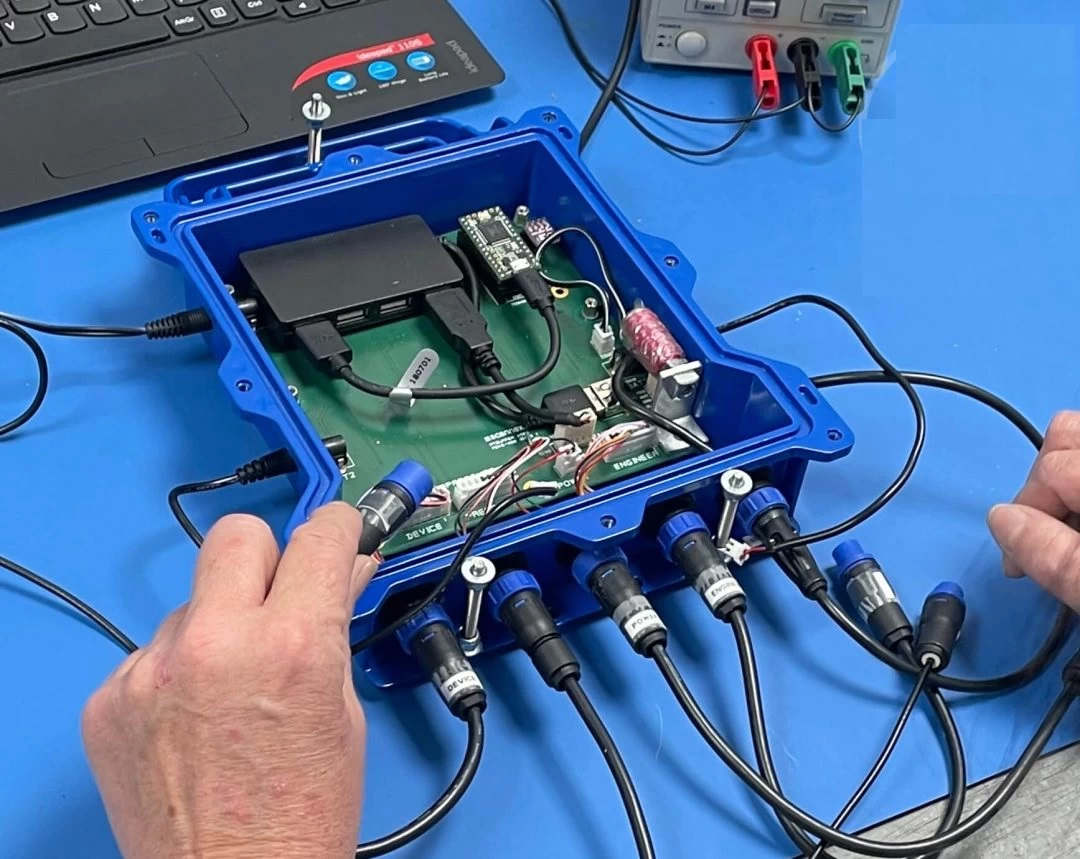

Cable and Harness Assembly

Whether using automated or manual tooling, our experienced assemblers will expertly manufacture your cable or harness assembly to the highest technical standards.

Engineering Services

We offer a broad range of technical solutions, including DFM, DFT, prototyping, process analysis, and customized manufacturing.

Exceptional Customer Service

Your dedicated customer service representative is always available to answer questions, make any needed changes, and manage the needs of your product from order placement to on-time delivery.

Full System Integration

Our skilled technicians can assemble and test your final electron-mechanical or medical product, ensuring that only properly finished and functioning products are shipped.

Quality Assurance and Regulatory Control

All our manufacturing facilities are ISO 9001, ISO14001 and 13485-registered. We comply fully with RoHS compliance.

Advanced Testing and Inspection

Our testing capabilities include 3D X-ray, flying probe test, ICT, conformal coating, functional testing, automated programming, and automated optical inspection (AOI).

Capabilities of Electronics Manufacturing Services

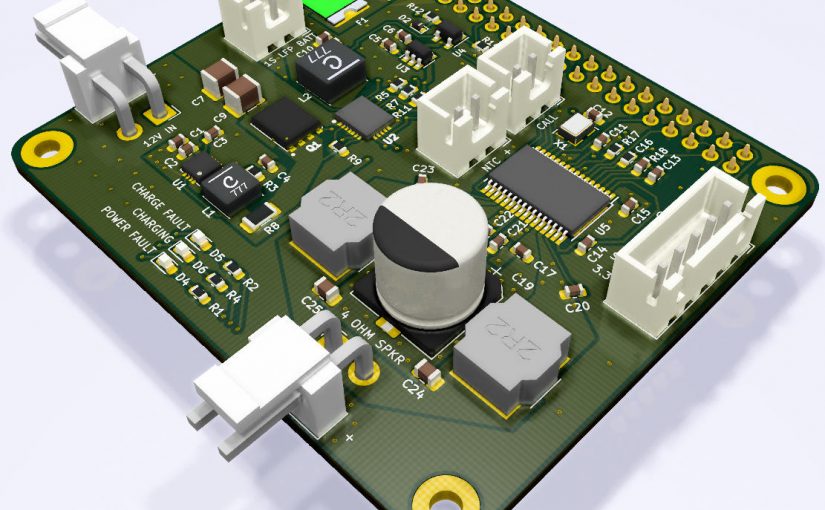

One of the primary services offered by electronic manufacturing services companies is streamline PCB fabrications process and advanced circuit board assembly capabilities. Modern technological improvements enable fast and high-quality PCB assembly due to precise component placement capabilities. A refined SMT assembly line can be a significant investment for an OEM, often costing millions of dollars. However, by leveraging the resources of electronic manufacturing services providers, OEMs gain access to state-of-the-art, quick, and flexible manufacturing lines for assembling complex electronic circuit boards at a fair cost.

At RockPCB’s manufacturing facility, we provide comprehensive assembly processes, including circuit board assembly, cable and harness assembly, box build assembly, and electromechanical assembly. Our services are complemented by thorough PCB testing methods, ensuring top-notch quality and reliability. By offering complete PCB assembly services, we allow OEMs to focus on their core competencies without needing to be directly involved in the manufacturing process.

Our electronic manufacturing services are designed to meet the diverse needs of our customers, delivering efficient and cost-effective solutions. By partnering with RockPCB, OEMs benefit from modern manufacturing techniques and reliable assembly processes, ensuring the best outcomes for their electronic products. Trust RockPCB for all your electronic manufacturing needs and experience the advantages of working with a leading provider in the industry.

Our Capabilities of Electronics Manufacturing:

- PCB assembly types: SMT Assembly, THT Assembly, and Mix technology

- Box Build Assembly, Turnkey Assembly, BGA Assembly

- High & Low Volume Assembly

- Conformal Coating Services

- Electromechanical assemblies

- Detailed Test and Inspection

- Design for Manufacturability (DFM)

- Design for Testing (DFT)

Testing protocols for Electronics Manufacturing include:

- Automated Optical Inspection

- In-circuit Testing

- X-ray testing

- Functional Testing

Advantages of Electronics Manufacturing Services

Here are the few advantages of Electronics Manufacturing Services (EMS).

Certificates for Electronics Manufacturing Services

Manufacturing Experience

With over 10+ years of expertise in electronics manufacturing, we deliver end-to-end solutions that bridge design intent and production reality. Our proven capabilities span high-mix, low-volume (HMLV) prototyping to high-volume manufacturing (HVM), serving industries from medical devices to automotive and aerospace.

Streamlined Process

Our one-stop electronics manufacturing services offer a streamlined process that eliminates the need for businesses to work with multiple vendors. This means that businesses can save time and resources by having all of their manufacturing needs met in one place. Additionally, working with a single vendor can help ensure consistency and quality throughout the manufacturing process.

Faster Time-to-Market

Our one-stop electronics manufacturing services can also help businesses bring customer’s products to market faster. By having all of customers manufacturing needs met in one place, businesses can avoid delays caused by coordinating with multiple vendors. Additionally, these services often have the expertise and resources needed to complete projects quickly and efficiently.

Cost Savings

Through using our one-stop electronics manufacturing service can also result in cost savings for businesses. By consolidating all of clients manufacturing needs with a single vendor, businesses can often negotiate better pricing and reduce overall costs. Additionally, these services may offer economies of scale that can further reduce costs.

We’re Here To Support You

Let’s Source

Smarter, Together.

Looking for a trusted partner to meet your electronics manufacturing needs? RockPCB. delivers reliability, speed, and quality — every time.

Together We Will Drive Your Success

Success in the electronic manufacturing services field requires each individual to pay close attention to detail from the beginning of the project to the very last part shipped.

We make it a point to make sure that what we deliver is exactly what you want, whether it’s a critical delivery turnaround or a specific drop-shipment to your customer. We look forward to working with you.

At RockPCB, we believe advanced technology innovation thrives through partnership. We are committed to being a pioneer in small-to-medium batch electronics manufacturing, we don’t just build high quality products or deliver cutting-edge solutions—we forge lasting collaborations that empower your vision.

Contact us now when you are looking for a trustable electronic manufacturing contractor.

General FAQs

1. What is Electronic Manufacturing Services (EMS)?

EMS includes through hole, wire harnesses, cable harnesses, surface mount technology and box builds to support assembly, technology, and design-driven services.

2. What is PCBA?

Your electronic circuits come to life physically with printed circuit board assembly (PCBA). To define electrical connectivity on a manufactured circuit board, layout software combines component placement and routing.

3. Why is PCBA important?

Without Printed Circuit Boards, electronically manufactured devices would not be able to function. They are essential in connecting different components and allowing for communication between them.

4. What Industries Rely on PCBs and PCBAs?

PCBs are commonly required for smartphones, computers, and Internet of Things (IoT) devices such as smart speakers. Household electronics such as microwaves and refrigerators also rely on PCB but increasingly PCBA supports Aerospace, Automotive, Government Defense Services and associated Communications markets.

5. What’s the Difference Between PCB and PCBA?

The PCB and the PCBA are the results of two different steps of the same process. A PCB is a blank circuit board without electronic components attached, whereas a PCBA is a completed assembly with all the necessary components to make the board function as needed. Unlike PCBs, PCBAs are ready for use in electronic devices.