PCB reverse engineering is the process of analyzing an existing printed circuit board (PCB) to understand its design, functionality, and components—typically to recreate, modify, repair, or improve the original board. This is done when original design documentation is unavailable, obsolete, or needs verification.

Destructive reverse engineering (DRE) is a process where all layers of the printed circuit board are imaged and subsequently removed by various milling techniques or tools.

Non-destructive PCB reverse engineering (NDRE) mean that the circuit board itself is not destroyed in the process. However, most non-destructive techniques require removing components from the surface of the board.

X-ray computed tomography-based imaging processes have advanced to the point that they are able to capture images of the circuit board well enough to isolate individual layers and the features on each of these layers.

Oftentimes a Flying Probe test machine (FPT machine) can also be used to generate data from a circuit board. Unlike destructive methods, with this process the PCB can generally be reused.

In addition, a schematic can be merged with the Bill of Materials (BOM) and component Pick and Place data to further enhance its usability in troubleshooting scenarios, or can be used as a base for the design of a brand new PCB. If a destructive reverse engineering process has been used or images for all PCB layers have been captured using X-ray imaging.

Whether the circuit board is reverse engineered using a destructive or non-destructive method, the result is that a net-list is obtained. While the net-list itself cannot be used to create an identical replacement, it can be used to generate supporting data for the board like a schematic drawing.

Legacy systems need maintenance and replacement parts to operate past their intended life cycle. Demand for parts that are no longer being manufactured can lead to material shortages of parts, called DMS/DMSMS.

The PCB stack-up design clearly defines each and every layer and its order, there should be physical labels on each layer for their accurate placement.

Solder mask is a layer of material applied to the circuit board to protect it and paste mask is the pattern used to apply the solder paste.

NC Drill file is also known as numeric control drill file. This indicates a file that regulates all the information relating to via or hole drilling requirements.

The plating on the through holes is copper, a conductor, so it allows electrical conductivity to travel through the board. Non-plated through holes do not have conductivity.

Blind vias are essential for high density multi-layer PCBs, allowing efficient and reliable connections between the various layers without resorting to traditional through-hole vias that span the entire board.

A PCB bill of materials (BOM) is a comprehensive list that provides information on all the components to be assembled on the printed circuit board.

One of the core benefits of PCB reverse engineering is its ability to recreate discontinued or obsolete PCBs. In many cases, the original equipment manufacturer (OEM) may no longer provide support or replacement parts for older equipment.

PCBs can develop faults and failures over time due to various reasons, including wear and tear, component degradation, or environmental factors. Understanding the design and components of a PCB through reverse engineering simplifies the diagnosis of faults.

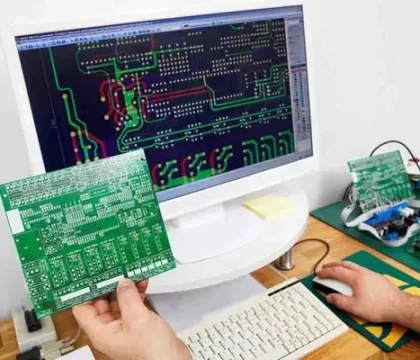

PCB Reverse engineering provides engineers with detailed schematics and a comprehensive understanding of a PCB’s initial design. This knowledge empowers them to suggest and implement custom modifications or improvements to the printed circuit board.

A printed circuit board reverse engineering can provide valuable insights into the inner workings of competitors’ products. Analyzing these products allows engineers to gain a deeper understanding of their design choices and functionality.

201, Block S, Hengyu, Science&Technology Park, No.1 Ruiji Rd, Nanlian Community, Longgang District, Shenzhen, China.

+86 755 8487 1176

At RockPCB, LLC. we strive to be your premier partner in technological design engineering, offering comprehensive solutions from circuit board design and layout to software and firmware development. Our mission is to provide applicable, intelligent solutions that propel our clients’ technologies forward.